| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Brand Name : AOXUANZG

Model Number : JH21-25T

Certification : CE,

Place of Origin : China

MOQ : 1 set

Price : $8000

Payment Terms : L/C, D/A, D/P, T/T

Supply Ability : 500 sets/ year

Delivery Time : 40 days after payment

Packaging Details : Fumigation Wooden Box

Type : Pneumatic Punching Machine Production Line

Slider Drive Mechanism : Screw Press

Precision : Hign Precision

Controlling Mode : CNC Type

Nominal Force : 250

Stroke of Nominal force : 3mm

Slide stroke : 80mm

Power Source : Pneumatic

Number of Strokers : 80-120 Times/min

Max.Die shut height : 250mm

Die shut height adjustment : 50mm

Distance from slide center line to machine body : 210mm

Worktable size : 400*700mm

Feeder size : Choose according to material width

Thickness of worktable plate : 70mm

Hole size of die handle : Ø40*60mm

Distance between columns : 450mm

Motor power : 3Kw

Specification : 1300MM(L)X1025MM(W)X2150MM(H)

Weight : 2600Kg

Origin : Maanshan, Anhui

Production desciption:

The pneumatic punch uses the high-pressure gas generated by the compressor to transport the compressed gas to the solenoid valve through the pipeline. The foot switch controls the action of the solenoid valve to control the work and return of the cylinder, thereby achieving the purpose of punching holes.

Feature:

This machine has a simple structure and low production cost. It adopts pneumatic technology, so that one air compressor can supply multiple pneumatic punching machines at the same time, which is more energy-saving than electric punching machines. Reduce power consumption. Simple operation, high safety, using foot switch to control the solenoid valve, simple structure, low failure rate, improving production efficiency.

Application:

Suitable for punching various metal and non-metal pipes and plates.

Equipment:

| •JIS I accuracy.v |

| •Steel welded frame with high rigidity. |

| •Motor with inverter. |

| •Combined wet friction clutch. |

| •Rectangular hexahedral lengthened guide; OCP-315/400 with octahedral lengthened guide. |

| •Hydraulic overload protector. |

| •Lifting balance cylinder. |

| •Imported dual solenoid valve. |

| •Elec.forced grease lubrication. |

| •Balance cylinder: manual oil lubrication. |

| •Integrated panel (elec.cam included). |

| •PLC control of international brand. |

| •Contactor and button of international brand. |

| •CE safety specifications |

| •Optional: air cushion, light curtain, automotive device, feeder. |

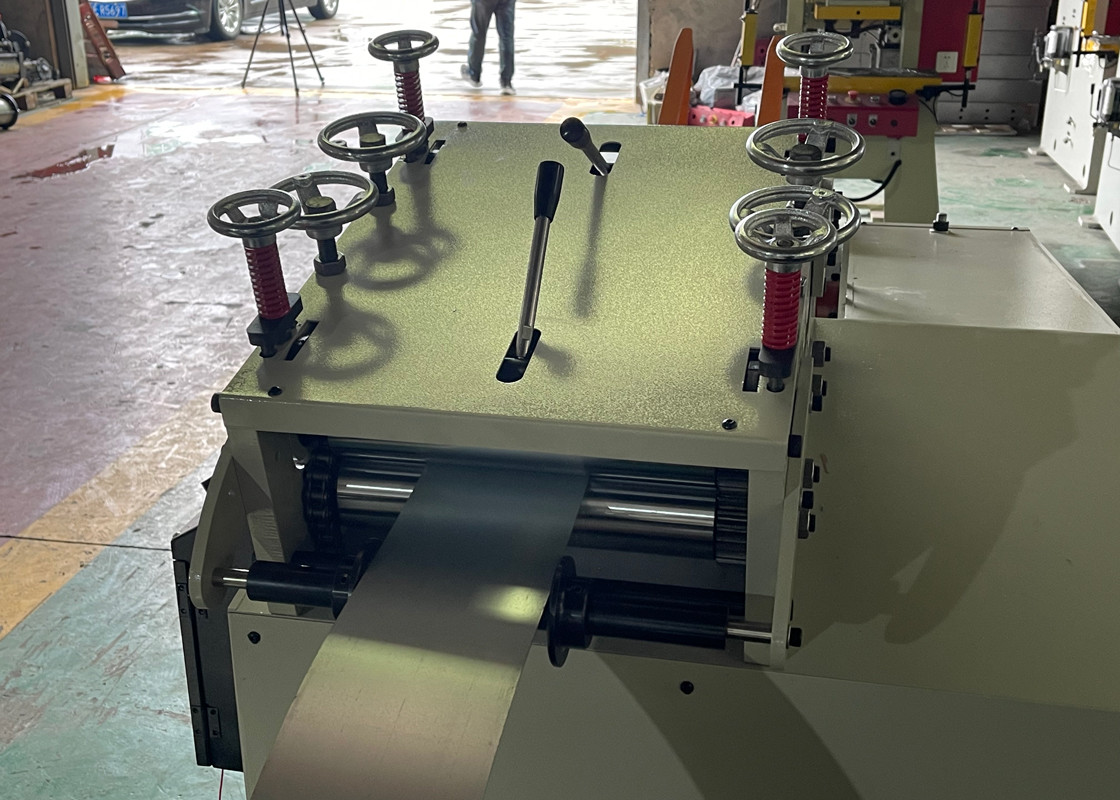

The feeder:

There are different sizes of feeders, and their selection is determined based on the material width given by the customer.

Details:

Technical Parameters:

| Technical Data: | ||

| Parameter | Unit | JH21-25T |

| Nominal Pressure | KN | 250 |

| Nominal Pressure Stroke | mm | 3 |

| slide stroke | mm | 80 |

| number of strokes | min | 80-120 |

| Max die set height | Mm | 250 |

| Die Height Adjustment | Mm | 50 |

| Distance from slider block centre to the frame | Mm | 200 |

| Working table size ( front -back X left-right) | Mm | 700*400 |

| Machine working table hole size | mm | 40 |

| Slide bottom size( front -back X left-right) | mm | 360*250 |

| Shank hole size(dia) | mm | Φ40 |

| Motor power | KW | 2.2 |

| Out size (L×W×H) | mm | 950 |

| 1594 | ||

| 2150 | ||

| Net weight | KG | 2500 |

Packing Detail:

Each Pneumatic punching machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers

and ship them abroad.

Delivery Detail:

Shipped in 30 days after payment.

Our Service :

Pre-sales.

* Project design, performance introduction, technical agreement, contract signing, packaging

* Inquiry and consulting support.

* Sample testing support.

In-sales.

* We will provide you with the latest progress in the product assembly, packaging and transportation.

After-sales.

* We will provide free accessories for the damage to non - human parts.

* Training how to install the machine, training how to use the machine with video and so on.

* And our technical staff can go abroad to provide technical guidance.

FAQ:

1. Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis/Conformance: Insurance: Origin, and other export documents where required.

2. What is the average lead time?

For samples the lead time is about 7 days. For mass production the lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when (1) we have received your deposit and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

3. What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or Alipay:30% deposit in advance, 70% balance before shipment.

4. What is the product warranty?

The warranty period is 13 months after the bill of lading date. We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone's satisfaction.

|

|

JH21-25 Small Pneumatic Punching Machine Stamping Workpiece Mold Customization With Feeder Images |